Fanuc Corp and Nvidia Forge New AI‑Driven Manufacturing Frontier

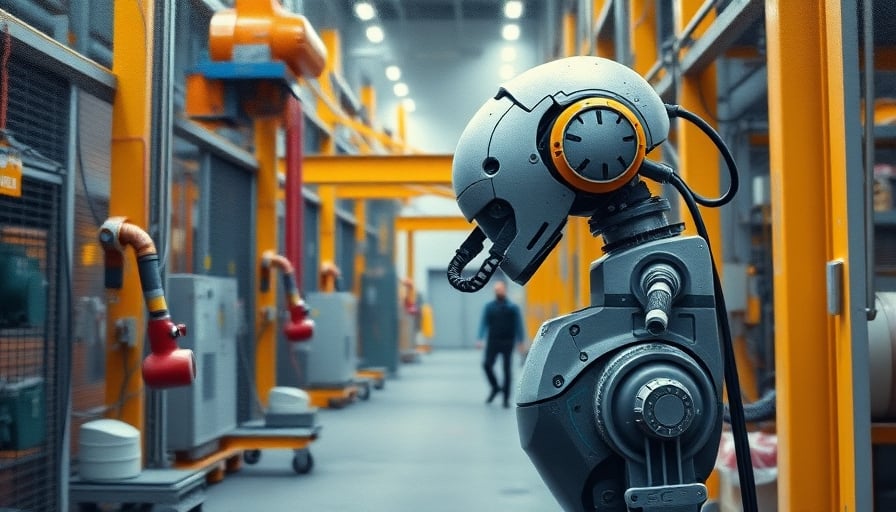

Fanuc Corp (Japan) today announced a strategic partnership with Nvidia Corp (USA) to embed artificial‑intelligence (AI) capabilities into its robotics and factory‑automation portfolio. The alliance aims to enhance the operational intelligence of Fanuc’s industrial robots, collaborative robots (cobots), and integrated automation systems, thereby positioning the company to capture the accelerating demand for smart, data‑centric manufacturing solutions.

Technological Integration and Product Implications

AI‑Enabled Sensor Fusion Fanuc’s robots will incorporate Nvidia’s TensorRT inference engine, enabling real‑time processing of multimodal sensor streams (LiDAR, vision cameras, force‑torque sensors). This capability allows robots to autonomously adjust kinematic trajectories, improve collision avoidance, and execute adaptive grasping without human‑mediated re‑programming.

Edge‑AI and Cloud‑Cooperation Leveraging Nvidia’s Jetson platform for edge inference and its RTX‑based GPUs for cloud‑based simulation, the partnership promises a hybrid architecture. Factory floor controllers can process high‑volume data locally, while complex neural‑network training occurs in the cloud, ensuring continuous improvement of motion planning algorithms.

Industry‑Specific Use Cases In automotive assembly, AI‑powered vision systems will detect minute surface defects in real time, triggering immediate re‑tooling. In electronics manufacturing, collaborative robots will use reinforcement learning to optimize pick‑and‑place sequences, reducing cycle times by up to 15 % in high‑volume scenarios.

Capital Expenditure Drivers

The global push toward Industry 4.0 has amplified capital outlays for intelligent automation. According to the International Federation of Robotics (IFR) 2024 report, robotics investment in manufacturing surged 12 % YoY, with 38 % of spending directed toward AI‑augmented systems. Key drivers include:

- Productivity Gains – AI‑enhanced robots can operate at 20–30 % higher throughput while maintaining safety compliance, translating directly into reduced labor costs and higher output per square meter.

- Labor Shortages – Aging workforces and geographic labor cost differentials incentivize automation that can fill skill gaps.

- Regulatory Compliance – Stricter safety and environmental regulations (e.g., ISO 45001, ISO 14001) are pushing firms to adopt predictive maintenance and energy‑efficiency algorithms embedded in AI systems.

Supply Chain and Infrastructure Considerations

- Component Availability – Nvidia’s supply chain, which includes high‑end GPUs and silicon photonics, faces periodic bottlenecks. Fanuc’s manufacturing partners must secure long‑term contracts to mitigate lead‑time variability, especially for low‑volume, high‑precision industrial robots.

- Data Connectivity – AI models require continuous data streams for training and inference. Investments in 5G, fiber‑optic networks, and edge‑cloud orchestration will be critical to support latency‑sensitive operations.

- Regulatory Landscape – Emerging data privacy laws (e.g., EU’s AI Act, US proposed regulations) may restrict the flow of sensor data across borders, influencing the design of on‑premise inference modules.

Market Implications

The alliance is poised to shift the competitive landscape:

- Differentiation – Fanuc’s longstanding reputation for robust, low‑maintenance robots will be amplified by AI‑driven adaptability, appealing to mid‑tier OEMs seeking cost‑effective yet sophisticated solutions.

- Pricing Pressure – Advanced AI capabilities may allow Fanuc to command premium pricing, but competitors that adopt similar technologies will intensify price competition.

- Ecosystem Expansion – The partnership opens avenues for co‑development of open‑source AI frameworks, potentially attracting system integrators and software vendors to the Fanuc ecosystem.

Outlook

While Fanuc has not disclosed specific operational or financial metrics, the collaboration signals a decisive move toward integrating AI at the core of industrial automation. Industry analysts anticipate a near‑term uptick in capital expenditures as manufacturers aim to retrofit legacy plants with AI‑enabled robotics, while also building new facilities optimized for data‑intensive processes. The success of this partnership will hinge on effective supply chain coordination, regulatory compliance, and the ability to deliver demonstrable productivity gains that justify the investment.