Corporate News

CNH Industrial NV Expands Academic Collaboration to Drive Innovation in Heavy Equipment

CNH Industrial NV (CNH) has reinforced its commitment to research, innovation, and sustainability by signing a new framework agreement with the University of Bologna. The pact, formalized by the university’s rector and the chief executive of CNH’s Italian subsidiary, seeks to deepen a long‑standing relationship and accelerate progress in the agricultural and construction equipment sectors.

Strategic Rationale

The partnership is aligned with CNH’s broader strategy to enhance its research capabilities and accelerate the deployment of sustainable technologies across its product portfolio. By engaging a leading European academic institution, CNH gains access to cutting‑edge research in manufacturing processes, materials science, and digital transformation—key drivers of productivity in heavy industry.

Manufacturing Process Optimisation

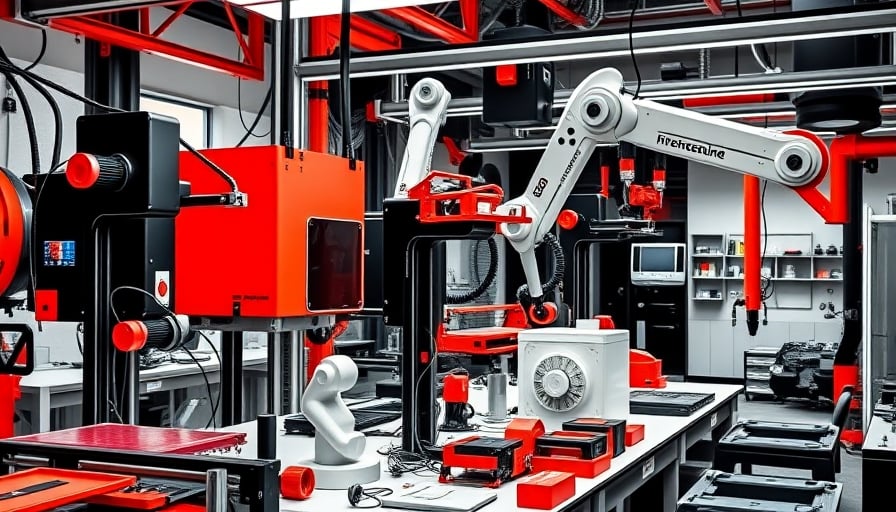

A central component of the collaboration will focus on refining manufacturing workflows for large‑scale equipment. Topics under consideration include:

| Process | Expected Improvement | Technological Focus |

|---|---|---|

| Additive Manufacturing | Reduction of part count by up to 30 % | Metal‑powder jetting for critical structural components |

| Robotic Assembly | Cycle‑time reduction of 15‑20 % | Collaborative cobots equipped with force‑feedback control |

| Predictive Maintenance | Downtime decrease by 25 % | AI‑driven condition‑monitoring of hydraulic systems |

By integrating advanced additive manufacturing techniques, CNH anticipates lower material waste and faster prototype cycles, directly enhancing capital efficiency. The deployment of collaborative robots will also free skilled labor for higher‑value tasks, improving labor productivity metrics.

Technological Innovation in Heavy Industry

CNH’s initiative aligns with broader industry trends toward digital twin simulation, autonomous operation, and electrified powertrains. The University of Bologna’s research strengths in smart manufacturing and sustainable power systems will enable CNH to:

- Develop digital twins for whole‑plant simulation, reducing commissioning times by 20 %.

- Advance battery‑electric drivetrains for construction equipment, targeting a 10 % improvement in power‑to‑weight ratio.

- Integrate Internet‑of‑Things (IoT) sensors for real‑time fleet analytics, supporting proactive service models.

These innovations are expected to lift CNH’s productivity index, defined as output per hour of capital, by an estimated 5 % over the next five years.

Capital Expenditure and Economic Drivers

Capital allocation decisions for CNH are driven by several macro‑economic factors:

| Factor | Impact on CAPEX |

|---|---|

| Interest Rate Environment | Lower rates reduce financing costs, encouraging equipment upgrades |

| Commodity Prices | Volatility in steel and aluminum can affect material cost forecasts |

| Regulatory Incentives | EU Green Deal subsidies boost investment in low‑emission technologies |

| Supply Chain Resilience | Diversification of component sourcing mitigates disruptions, justifying new production lines |

The partnership also positions CNH to qualify for European Union funds aimed at green transformation, potentially offsetting a portion of the investment required to implement the new manufacturing technologies.

Supply Chain and Infrastructure Implications

The collaboration will influence CNH’s supply chain structure in several ways:

- Localised Production: Developing new component manufacturing processes in Italy can reduce lead times and logistics costs.

- Supplier Engagement: CNH will involve key suppliers in joint development workshops to standardise advanced manufacturing modules.

- Infrastructure Investment: Upgrading plant facilities to accommodate additive manufacturing and high‑speed robotics will necessitate significant civil and electrical infrastructure upgrades.

Regulatory changes, particularly those related to environmental emissions and digital data security, will be incorporated into the design of new production lines. CNH will also align its data governance practices with the EU’s Digital Operational Resilience Act (DORA) to ensure compliance and operational continuity.

Market Implications

By integrating these technological advancements, CNH is poised to:

- Increase Market Share: Offering higher‑performance, sustainable equipment can capture emerging segments in developing economies.

- Enhance Profit Margins: Reduced manufacturing costs and improved asset utilization translate into lower cost of goods sold.

- Strengthen Brand Reputation: Demonstrated leadership in sustainability will resonate with institutional buyers and investors focused on ESG criteria.

While the agreement does not disclose operational or financial specifics, the strategic alignment between CNH and the University of Bologna signals a commitment to long‑term value creation through scientific collaboration and industrial innovation.