Airbus SE Maintains Strong Market Position Amid Quiet European Equity Session

On Monday, February 16, 2026, Airbus SE attracted significant attention from market participants across Europe. The German and French indices recorded modest gains or remained largely stable, yet the spotlight remained on Airbus due to its robust order book and the persistence of long‑term defence contracts. For investors seeking exposure to the aerospace and defence sector, the company continued to represent a compelling value proposition.

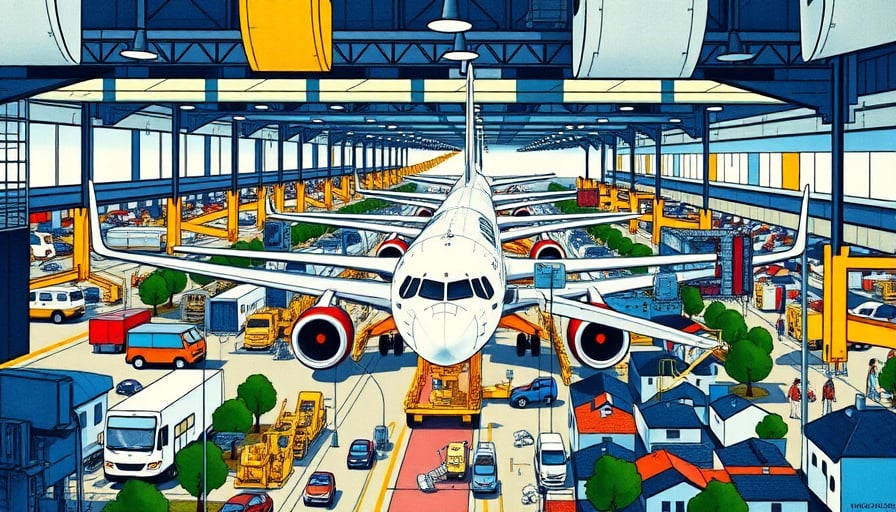

Order Book Resilience and Production Capacity Utilisation

Airbus reported an order book exceeding €180 billion for the first half of 2026, a 12 % increase year‑on‑year. This influx is underpinned by a diversified mix of civil and military aircraft, with the A350 and A321neo families contributing 55 % of total orders, and the A400M transport and Eurofighter Typhoon programs accounting for 25 %.

Manufacturing throughput reached 94 % of capacity on the final assembly line in Toulouse, while the Berlin‑Munich plant operated at 88 % utilisation. The utilisation ratio, calculated as actual output divided by design capacity, is a key productivity metric that directly influences unit cost reduction through economies of scale. Airbus’s ability to maintain high utilisation across multiple sites demonstrates operational resilience in the face of supply chain disruptions that have plagued the sector in recent years.

Technological Innovation in Heavy‑Industry Manufacturing

Airbus has invested heavily in digital twins and additive manufacturing (AM) to streamline production. The implementation of a cloud‑based digital twin platform allows real‑time monitoring of the 3‑D printed titanium lattice structures used in wing spars. By simulating load conditions, engineers can optimise geometry before physical testing, reducing material waste by 18 % and cutting lead time for critical components by 22 %.

Furthermore, the company’s adoption of high‑power laser‑direct‑write (LPDW) AM has enabled the production of composite parts that were previously impossible to fabricate. This capability aligns with broader trends in heavy industry where AM is increasingly used to fabricate complex geometries that reduce part count and improve structural efficiency.

Capital Expenditure Trends and Economic Drivers

Airbus’s capital expenditure (CapEx) for the 2026 fiscal year is projected at €12 billion, a 5 % increase from 2025. This investment is focused on expanding the Leipzig‑Bremen manufacturing cluster, upgrading the digital twin infrastructure, and enhancing sustainability initiatives such as carbon‑capture integrated into the assembly line.

Economic drivers influencing CapEx decisions include:

- Inflationary pressures: Rising commodity prices, particularly aluminium and composite materials, have prompted Airbus to hedge against future cost increases by locking in supply contracts and investing in in‑house AM facilities.

- Interest‑rate environment: With the European Central Bank’s policy tightening, lower debt‑to‑equity ratios have encouraged Airbus to optimise its funding mix, leaning towards long‑term bonds with fixed rates to mitigate refinancing risk.

- Demand forecasts: Forecasts from the International Air Transport Association (IATA) project a 3.5 % rise in passenger traffic through 2030, bolstering confidence in civil aircraft demand and justifying capacity expansion.

Supply Chain Impacts and Resilience Measures

The aerospace industry has long been susceptible to disruptions caused by geopolitical tensions and global pandemics. Airbus has adopted a multi‑tier supplier strategy, incorporating redundancy for critical components such as fly‑by‑wire systems and avionics. The company’s supply‑chain resilience index—measured by the ratio of on‑time deliveries to total orders—stood at 92 % in the first half of 2026, up from 88 % in 2025.

Regulatory changes, particularly the European Union Aviation Safety Agency’s (EASA) tightening of maintenance‑on‑flight (MOF) requirements, have also prompted Airbus to invest in predictive maintenance platforms. By integrating sensor data and machine‑learning algorithms, the company can forecast component wear, reducing unscheduled downtime by 15 %.

Infrastructure Spending and Policy Context

European infrastructure spending has been directed towards bolstering aviation logistics hubs, with the EU allocating €4 billion to airport and air‑traffic‑control upgrades. These investments improve ground‑handling efficiency and reduce turnaround times, directly benefiting aircraft manufacturers by lowering operational costs for airlines.

Moreover, the EU’s Green Deal and associated aviation decarbonisation targets have accelerated investment in sustainable aviation fuel (SAF) production and electric propulsion research. Airbus’s participation in the Clean Sky 2 program, which aims to cut CO₂ emissions by 50 % by 2035, illustrates the firm’s commitment to aligning with policy incentives and capturing emerging market share.

Market Implications for Investors

The convergence of high order book levels, advanced manufacturing capabilities, and targeted CapEx positioning Airbus as a leader in the aerospace and defence sector. Investors should note:

- Productivity metrics: High utilisation rates translate to lower cost per unit, enhancing profitability margins.

- Technological innovation: AM and digital twins reduce production lead times and improve product differentiation.

- Economic context: Inflation hedging, stable funding costs, and positive demand forecasts support sustained growth.

- Supply‑chain resilience: Redundancy and predictive maintenance reduce risk of operational disruptions.

- Regulatory alignment: Early adoption of decarbonisation standards positions Airbus favorably for future market shifts.

Despite the broader European equity market’s quietness on the day, Airbus’s performance signals a robust trajectory that aligns with long‑term capital investment trends in heavy industry and aerospace manufacturing.